With the deepening of Made-in-China 2025 and industry 4.0 concepts, production, equipment and logistics industry is facing a comprehensive upgrade; smart logistics gets more and more attention as one of three cores Industry 4.0.

SAIC-GM logistics relies on the company's core strategy of intelligent manufacturing, implements annual theme of “dual-drive linkage for efficiency and innovation”,focuses on difficulty, analyzes bottleneck, and continually seeks to improve and enhance technical innovation and application. Dongyue automatic sorting center is one of the achievements.

[Project Background]

Three-dimensional warehouse of automation technology as a high-end technology is often used in medicine, retail and other industries, and it is the first time to apply to automobile parts management in China. In the project development process we are faced with the challenge of “two-various, two-high and two-difficult dilemma ".

1. " Two-various" means many kinds of materials and packing cases. There are several thousands of materials in Dongyue automobile company with great difference in appearance, volume and weight; over several hundreds of packages with different material, dimension and shape, which requires much for standardization of automation equipments like three - dimensional warehouse, and it is difficult to meet the demand with high differentiation.

2. "Two-high" means high production cycle time and throughput flow. Dongyue automobile company runs in high tempo and one vehicle is offline every 57 seconds on average, material throughput is as high as 2000boxes per hour, which requires high timeliness and brings about great challenges to the whole operation process of material receiving, warehousing and online production.

3. "Two-difficult" means the difficult in system development and interaction. Business needs include receiving, warehousing, de-warehousing, and full-access / sorting, re-warehousing and so on, operation mode is complicated and system development is from scratch; there is large amount of data interaction between solid warehouse system and system of automobile company with multiple interfaces, and is difficult for system command compatibility.

Faced with multiple challenges, SAIC-GM and Shanghai Anji, Yantai Anji Tonghui make in-depth integration and establish project team under support of headquarters leaders. Firstly, through detailed analysis of site operation process and underlying data, develop several drafts for different material variant, packing measurement, throughput flow rate, operation mode, etc, a final program of pallet-level solid warehouse is finally determined after continuous review and improvement. Next, Safety And Fire Protection Department, It Department, Manufacturing Engineering, Department Of Business Planning And Manufacturing Systems, Final Assembly participate in the whole process, meetings are convened for many time to discuss the project safety program, system program, technology agreement, technique specification, and supplier training about GDHS ( health and safety regulations ) and power-up process is also carried out. Relevant parties work closely to develop detailed implementation plans, venue planning and shelf arrangement, equipment pre-acceptance and installation, construction process quality inspection, system debug and commissioning are done systematically, and it takes only 169 days to realize smooth operation.

Overview of sorting center

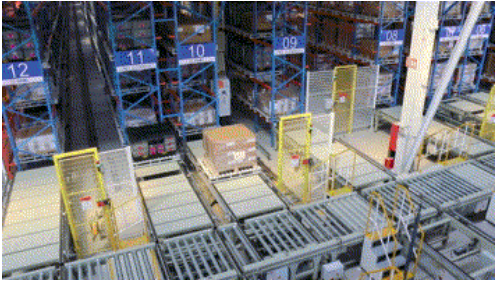

Dongyue automatic sorting center is made of altitude automatic warehouse district and automatic transport sorting line. Warehouse area is 4000㎡, transport sorting line is 800㎡, there are 4 sets of stacking machine and 6 laneways, and about 3500 pallet locations. The project introduces innovative technologies such as side track transferring, visual identification, automatic dispatch, system real time interaction, and differential locator. Comprehensive reform of wood pallet warehousing, storage, sorting is made from the aspects of safety, efficiency and cost to realize automation and intellectualization of wood pallet transfer, hand operation is replaced with automatic equipment, which greatly enhance wood pallet transferring efficiency, saves about 1.8 million Yuan per year and greatly enhance supply chain automation.

[Operation]

Warehousing

The whole pallet of material is moved to warehousing transport line to flow to the altitude storage rack when material needs warehousing.

Stacking machine send the whole pallet to designated location for storage as per instruction from system;

Ex-warehouse

Solid warehouse system receives demand from WMS; stacking machine takes the specified pallet from target location.

Stacking machine put the pallet onto transport line;

Transport line send pallet to specified export as per demand and the shuttle train send it to target Dolly;

Original pallet is returned;

Automatic sorting center original pallet automatic stacking and re-splitting design can increase origin pallet storage buffer and shortens length of transport line;

Advanced automatic sorting center highly improves warehouse usage, replaces staff with automatic machine and control technique, and makes site work safer, more standardized and efficient.

Completion of Dongyue Automatic Sorting Center is a miniature of continual renovation to traditional operation mode and active exploration of new technique and mode in SAIC-GM Logistics. One swallow does not make a summer, SAIC-GM has many achievements on the road of promoting intelligence logistics, projects such as new energy battery application, automatic empty box sorting, automatic sorting robot, vehicle shipping automatic scanning are being implemented one after another.

Banishing traditional lead-acid battery, new ferric phosphate lithium cell is in the nature of high safety, low cost, high efficiency and zero pollution. There is no factory with experience of large-scale application of LFP batteries in the entire auto industry before. After research for over 2 years, there are nearly 100 sets of mobile equipments with new LFP batteries working in Dongyue logistics field, which account for 25% of all mobile logistics equipments in Dongyue bases. It is expected to reduce energy consumption by 35%, reduce production of 432 tons of dangerous waste, eliminate the risk of hydrogen generated explosion during charging, and shorten the battery charging time by 87%, decrease battery turnover quantity by 67% and save annual cost of more than 10 million Yuan.

Automatic empty box circulating transport chain is designed based on characteristics of field operations, store bunkers to maximally in limited space, which can balance peaks and troughs of bunker sorting, improve man-machine engineering, improve staff work efficiency by 70% and decrease waste and waiting.

Automatic sorting robot

Robots have been widely used in workshop production with its efficiency, accuracy and stability, such as workshop welding robot, glue robot. Through the comparative analysis of business models, in 2018 Dongyue logistics will replace worker with robot of artificial vision system to lift tire from bunker to conveyor line by advantage of auxiliary spreader.

Vehicle shipping automatic scanning

Application of RFID (radio frequency) technology in vehicle warehouse management system makes automation and visualization of each step of vehicle warehouse and achieves scanning spot full coverage, commercial vehicle control without blind spot and cycle scanning time shortened by 4 seconds.

Looking ahead, SAIC - GM - logistics will join hands with Anji Tonghui and other strategic partners to ride on the momentum, realize logistics layout with intelligent planning, smart decisions and smart warning such as real-time linkage of production, selling and storage, digitalization and real - time simulation analysis of the whole logistics process, information interconnection of the whole process of supply chain, as well as resource planning, logistics fully automated unmanned warehouse, optimal management of the whole channel inventory, and assist SGM to maintain its leading position in the automotive industry.